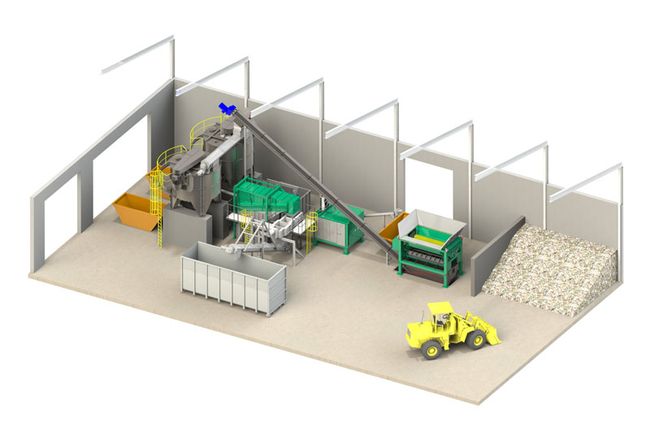

Stationary Systems

Stationary Equipment/Systems

As Canada’s leading recycling systems integrator, our stationary systems are the infrastructure of facilities across the country.

Stationary equipment is designed for permanent installations that do not require the machinery to be moved intermittently to service different logisitical needs. They offer all of the performance of mobile equipment without the diesel fumes, the drivetrain components and the added costs they bring.

SINGLE-SHAFT SHREDDER

The Terminator is a slow speed, high torque single-shaft shredder for hard-to-shred waste. C&D, railroad ties, carpet, MSW and tires are no problem for the rugged teeth mounted on the shredding drum and opposing counter comb. The stepless cutting gap allows adjustment of the size of the output material.

TERMINATOR DIRECT

Power is delivered by an electric motor with minimal maintenance and transfered to the shredding drum by a mechanical drive with optimum efficiency.

TERMINATOR STATIONARY

A new engine compartment with large doors offers perfect access to all drive components. In addition, the separation of the drive unit from the shredding unit is provided as an option. The advantages: Better protection of drive unit and space-saving integration into the process cycle.

DUAL-SHAFT SHREDDER FOR WOOD & GREEN WASTE

The stationary Crambo shreds all types of wood and green waste to a set particle size. Slow-running screws with shredding tools minimize fine particle and noise/dust emissions, and build up resistance to contamination. The particle size is adjustable by simply exchanging screen baskets.

The drum drive offers a choice between highly efficient mechanical drum drive with automatic transmission (Crambo direct) or the familiar hydraulic drive with load-dependent speed regulation. For the hydraulic system the separation of the drive unit from the shredding unit is provided as an option.

CRAMBO DIRECT

- Electric motor with 160-280 kW

- Mechanical drum drive

- Drive and shredding unit combined

CRAMBO STATIONARY

- Electric motor with 160-320 kW

- Hydraulic drum drive

- Drive and shredding unit combined or separated

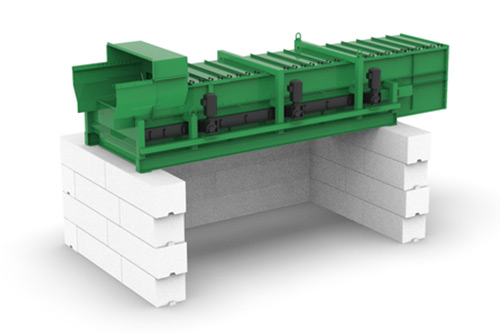

STATIONARY STAR SCREENS (MULTISTAR 2-SE)

Star screen technology from Komptech is regarded as one of the most effective separation methods for organic waste. Precise separation selectivity regardless of material moisture, and particle size change at the press of a button are particular features of the Multistar star screen. Its compact design makes the Multistar 2-SE star screen system simple to integrate. Its modular design and options such as underbody, feed metering container with feed and discharge belts, windsifting, etc. ensure customer requirements can be met perfectly.

STATIONARY STAR SCREENS (MULTISTAR 3-SE)

Multistar star screens are not only among the most powerful screening machines, they are also unparalleled in operating efficiency. Compost, bark and biomass are separated extremely reliably and quietly. Stationary Multistar star screen systems leave no customer requirement unaddressed. With its modular design, screen decks, feed metering container, wind sifter and stone/- magnet separation are tailored perfectly to the job at hand, generating up to 4 fractions in one operation.

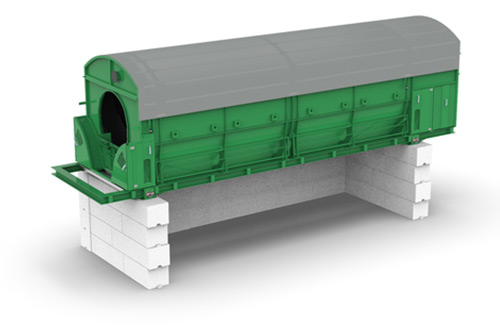

STATIONARY DRUM SCREENS

With stationary drum screens, a corresponding screening machine is available for every system size. Directly driven heavy-duty supporting wheels (1845/2055: DRUMGRIP-drive) provide quiet drum operation and top efficiency with reduced energy consumption and noise emissions. Variable configuration of sub-structure, servicing accessibility, enclosure and drive simplify adaptation to on-site conditions.

STATIONARY BALLISTIC SEPARATOR

The Ballistor is used to separate out usable fractions from waste and potential recyclables. By combining ballistic separation with screening, separation is performed in one operation in accordance with the criteria 3/2-dimensional, rolling-cubic-rigid/flat-soft-narrow, or undersized/oversized particles.

With a choice of separation into three or four fractions, five sizes and many options, the Ballistor separator can be configured to suit the application.